Specialists in the Design, Production and Supply

of Miniature Fluid Control Solutions

Delivering the highest quality products and services to our customers worldwide

We are proud to offer an expansive portfolio of fluid management components. We supply a range of markets and support smaller customers through to large medical device manufacturers.

We have invested in a range of production facilities to develop comprehensive service capabilities. As a valuable resource for manufacturers, we are a reliable and specialist partner to supply niche areas of production.

Custom Design & Assembly Solutions

From customisable filters and check valves to comprehensive production capabilities, our knowledge of materials, product design and assembly services are unrivalled.

Within our manufacturing capabilities we offer bespoke product design, working with you from concept to full production including design, prototyping and test procedures. Our wide range of connection options for tube sub-assemblies enables us to provide customised solutions for flow control applications including manifold assemblies in a variety of materials.

X

Bespoke Product Design

We are a trusted partner to organisations of every size who require bespoke component design services. From small batch quantities to large scale production, we support organisations of all sizes requiring our specialist knowledge and expertise. We use the latest design and production technology giving complete quality assurance to our customers.

Learn more >

X

Cleanroom Facilities

Our ISO accredited 7, 8 and 9 cleanrooms enable us to provide packing and custom sub-assembly production for markets that include medical OEM's. With a wide component selection, we supply medical device companies and other industries who require precision component production.

Learn more >

X

Sub-Assembly Production

We are a recognised supplier of sub-assembly products such as tubing and manifold assemblies. Our highly experienced design engineers and assembly teams offer what is a key competence at The West Group. Our development of high quality sub-assembly solutions for the medical and scientific fluid control market makes us a key resource to device and system manufacturers.

Learn more >

X

Component Testing & Inspection

The West Group conforms with the tightest and most exacting component quality standards using the latest inspection and testing methods and equipment. This ensures our fluid control components and sub-assemblies meet or exceed operational functionality and quality.

Learn more >

X

Kitting and Packing

Our kitting and packing service supplies dedicated components sets or sub-assemblies that manufacturers can purchase with a single product code. Our product kitting solutions significantly benefit customers looking for component supply reliability, a reduced supplier base and improved service delivery.

Learn more >

X

Component Marking

Our investment in advanced tooling and techniques enables us to extend our service portfolio to encompass complete component identification. Should you require component batch tracing, serial number identification or simply wish to give your brand greater visibility by laser etching your logo, we can fulfil this requirement.

Learn more >

Click on the images below to find out more

'See Inside' our new capability brochure

If you would like to view a snapshot of our component categories and product range, click here to 'see inside' the latest TWG capability brochure.

Our miniature fluid control component range is extensive and we continually innovate in terms of design, materials and product developments. To view each category and its components in more detail, visit our products overview page. Our capabilities are as extensive as our components, details of which can be viewed on our capabilities page.

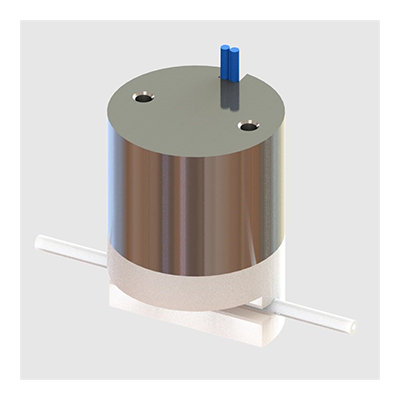

Our ISO Class 7 Cleanroom production facility enhances our miniature component manufacturing, production and post-production capability. Available as a standalone service or an add-on to our miniature component range, we offer an industry leading resource for the medical and scientific industry.

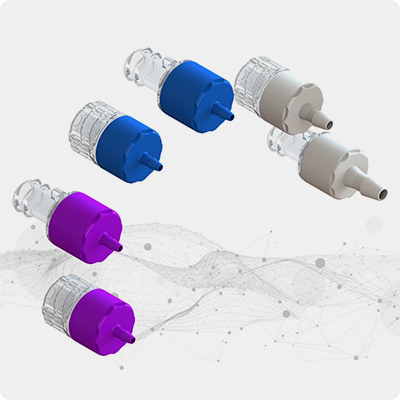

When a new project requires a filter or check valve, we understand that each customer has different requirements. With our flexibility and knowledge, TWG can help to provide an off-the-shelf solution, with multiple ways of achieving the correct inlet/outlet connection required.