How TWG serves the inkjet industry

Published date: 07 Jan 2025

With a long history of work in the inkjet market, The West Group Ltd understands the requirements and reliability that is expected when printing twenty-four hours a day, seven days a week. The solutions that we provide to customers in the inkjet market play a crucial role in ensuring the smooth functioning of inkjet systems, with little margin for error when it comes to the degradation of plastics in contact with ink.

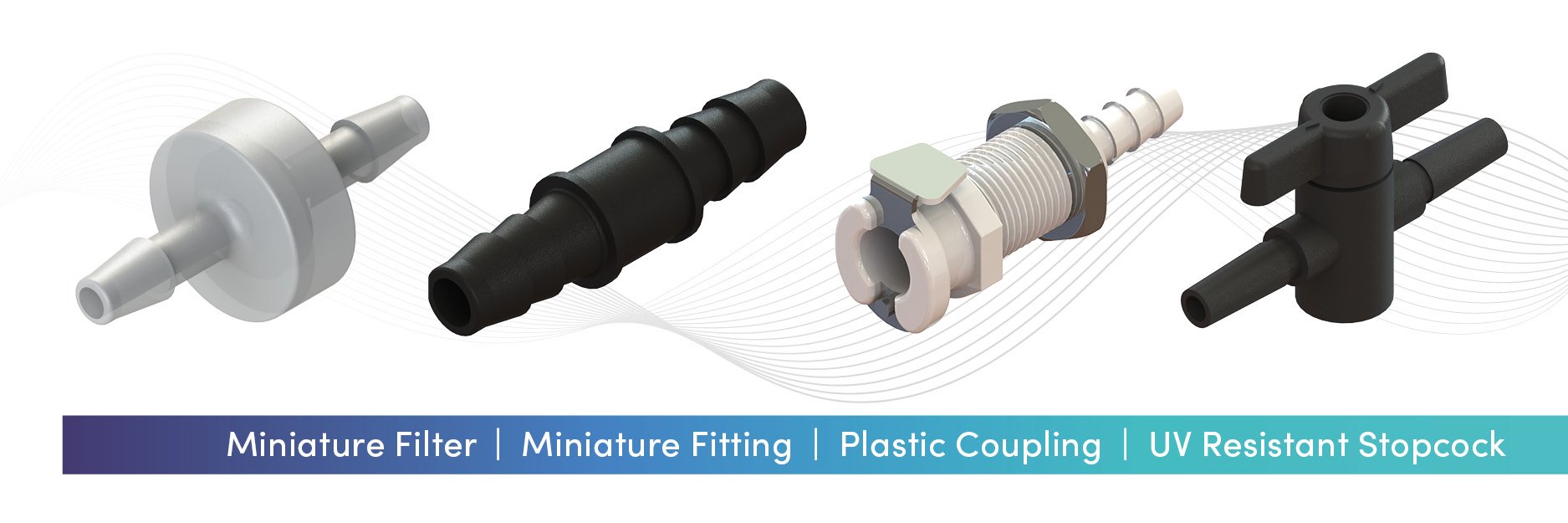

In an inkjet system, printers rely on precise and controlled delivery systems to deposit ink onto the paper. Fluidic components like our luer fittings, Filters, Quick Connects, check valves, and isolation valves form an integral part of this system, and facilitate the seamless connection of ink supply lines, printheads and cartridges. Providing secure connections and efficient sealing.

Specialised inks are used in the inkjet process and contain a variety of chemical formulations, including colourants, solvents, and additives. With this in mind, fittings and other flow control solutions with high chemical resistance are imperative to their long-term functionality as exposure to these inks can heavily increase the rate at which these products degrade. In terms of seals, this degradation can lead to leaks which is not only messy but could also compromise the functionality of other aspects of the machinery itself. The West Group are experts in chemical compatibility and are well placed to advise you on the media you are using.

Some of the more popular materials utilised in inkjet systems are:

Polypropylene: A thermoplastic polymer known for its excellent compatibility with inks, high chemical resistance, and low water absorption. Polypropylene’s durability and flexibility further enhances its ability to be used in Inkjet systems, as it can withstand the mechanical stresses and cycles associated with the printing process.

Nylon: A versatile and durable synthetic polymer, demonstrating good compatibility with inkjet inks. Its strong chemical resistance enables it to withstand the solvents and pigments found in inkjet inks without experiencing significant degradation.

Kynar: This thermoplastic offers a balance of performance properties, with a resistance to harsh chemicals, as well as thermal and ultraviolent environments. This resistance to UV makes it an ideal material for items like stopcocks and other fittings, as inks that are sensitive to UV are shielded and prevented from curing prematurely.